When you think of the manliest way of shaving, your mind undoubtedly goes to your great-grandpa’s tool of choice: the straight-edge razor. You may have thought about owning one, but immediately dismissed the idea for a host of reasons. They can be expensive, delicate, mastering their use is a real art, and so on.

And while this article won’t go into how to shave with one (Brett’s got a great write-up here on how to shave with a straight razor for beginners), we will certainly address the other concerns that may have stopped you from getting back to the roots of shaving with the luxurious and thrilling experience of using a straight razor. Today we’re going to give you a primer on how you can pick up a top-quality used straight razor on the cheap and then restore it yourself to its former glory. Soon you’ll be reminding yourself that you’re alive each morning, by placing a razor-sharp blade next to your neck!

The Ropes

Before you set out trying to find, learn about, restore, and eventually shave with a straight razor, it’s a good idea to learn “the ropes” of this new hobby.

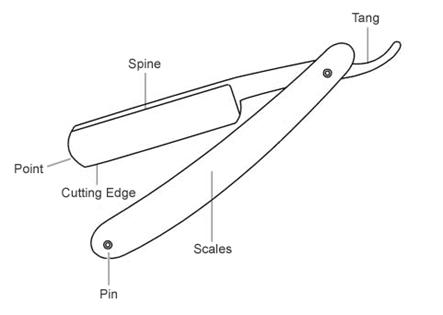

First, you need to get acquainted with the parts of a straight razor:

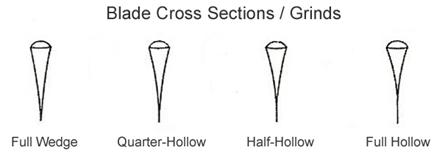

There are also two major “grinds” of straight razors—the Hollow Ground and the Wedge (and a few in-between):

Wedge style blades are generally larger and require more time/effort to hone or sharpen whereas the hollow-ground blades trade mass for convenience in regards to upkeep. Both perform terrifically, and it is generally recommended that people new to straight razor shaving start with a hollow ground, mainly because of the ability to sharpen it with ease. Luckily, most of the straights you’ll find are some type of a hollow-ground!

Wedge style blades are generally larger and require more time/effort to hone or sharpen whereas the hollow-ground blades trade mass for convenience in regards to upkeep. Both perform terrifically, and it is generally recommended that people new to straight razor shaving start with a hollow ground, mainly because of the ability to sharpen it with ease. Luckily, most of the straights you’ll find are some type of a hollow-ground!

Where to Get ‘Em

While newly made blades are available from companies like Dovo and Muhle, finding a vintage straight razor is not only more economical, but can often prove to pack more punch for the time and money you invest into it. Like anything made in the 19th and early 20th centuries, vintage straight razors can be found in very high grades of steel from classic old world cutlery empires such as England, Sweden, and Germany. However, you may be asking yourself, where do you find such a razor?

The first place to look could be closer than you think. Check with the older members of your family to see if an uncle or grandfather had a straight razor that’s been kept throughout the years. Chances are you may either find a straight razor or another cool keepsake such as a shaving mug or brush. If you don’t turn up anything here, worry not because a day of antique shopping around your city could just as easily result in making your first razor score. Oftentimes you’ll find straight razors in display cases along with other manly items like watches, cufflinks, eye-glasses, pens, coins, wallets, pipes or flasks. It may also be a good idea to let the shopkeeper know what you’re looking for because often small items like this can be hard to spot.

If you’re fortunate enough to find a vintage straight razor, remember that not all razors are made equally, and likewise not everything you find is worth purchasing. This brings us to the next important topic to consider.

What to Look For

Back in the heyday of straight razor manufacturing, there were literally hundreds of cutlery companies across the world making razor blades for sale. However, in the straight razor community of today, there are several common manufacturers that have a proven track record and are generally agreed upon as having a long lasting quality, grade of steel, and ability to hold an edge while delivering a comfortable shave. On a larger level, it is also known that some of the best straight razors came out of a select few parts of the world known for metallurgy.

Solingen, Germany – often referred to as “The City of Blades,” this German town (pronounced ZO-ling-en) is responsible for some of the best known blades in the world, past and present. Great manufacturers from this city include:

Solingen, Germany – often referred to as “The City of Blades,” this German town (pronounced ZO-ling-en) is responsible for some of the best known blades in the world, past and present. Great manufacturers from this city include:

- Bartmann

- Dorko

- Dovo

- Dubl Duck

- H. Böker & Company

- J.A. Henkels

- PAX

- Puma

Sheffield, England – Considered by some as the world’s cutlery empire in Europe throughout the 19th and 20th centuries. Popular manufacturers from this city include:

- Fredrick Reynolds

- George Wostenholm

- Joseph Allen & Sons

- Joseph Elliot

- Joseph Rodgers & Sons

- Wade & Butcher

United States of America – Many parts of the country such as New York, Louisiana, and Massachusetts were cutlery centers around the turn of the century and put out fine straight razors of several makes:

- Case / “Red Imp”

- Clauss

- Genco Cutlery Company

- Geneva Cutlery Company

- J.R. Torrey

- Ontario Cutlery Company

- Shumate Razor Co.

Other Notable Brands

- C.V. Heljestrand of Eskilstuna, Sweden

- Thiers Issard & Le Grelot of France

- Filarmonica from Spain

What to Avoid

Undoubtedly when you’re out hunting for straight razors, you’re going to come across some blades that should be passed over. Here’s a brief list of things to avoid:

- Razor blades with chips in them, especially near the cutting edge.

- Razor blades with burn marks or notable discoloration as this can represent heat-damage.

- Razor blades with substantial rust or deep pitting, especially near the cutting edge.

- Razors that have a flattened spine and/or lots of scratch marks at the spine. This represents large amounts of honing, reducing the life of the blade.

- Razors made in Pakistan.

If you find a razor from one of the cities or makers recommended above, chances are you are holding a great piece of tempered steel that should be able to take a keen cutting edge capable of providing a terrific shave. Good razors can be found anywhere from $5-$50, which is a steal when you consider that it should provide you a lifetime of shaving.

Whatever you get, it is likely to be very dirty, rusted, or covered in soap scum so now you need to know how to clean it up.

Restoring Your Vintage Straight Razor

So when you find an old straight razor at an antique store or via the web, it will likely be in some state of disrepair. It’s not uncommon to find a straight razor looking like this:

To restore a straight razor, there are two major areas to cover: 1) Cosmetics and 2) Cutting Edge. We’re only going to cover the cosmetic restoration topic, because a terrific article on sharpening the cutting edge can be found here.

Cosmetics

The blade of most vintage straights will at least have some kind of patina or natural darkening of the metal due to age. Others may have various stages of rust on them from improper storage over time. Even the handles or “scales” may need some cleaning up in order to look good again. Products that you’ll need for this work can be found at your local hardware store. Here’s how to start the revival:

1) Using sandpaper or a power tool such as a Dremel, re-surface the blade to remove rust and get it evenly smooth. You’ll likely have to progress through stages of sanding wheels with several different grits. If your blade has heavy rust or pits, you’ll want to start with the lower grits like 320. Finish up with grits beyond 10,000 and you’ll start to see a mirror finish. Long and even strokes lengthwise across the blade work best, and remember to take your time and exhibit patience with this process.

2) Switch to miniature buffing wheels for your power tool and use a metal polishing compound such as jeweler’s rouge or MAAS to get the blade looking shiny. This process works well in removing surface patina or light scratches and other cosmetic flaws.

3) Next, clean up the scales and pins using the buffing wheels and a polishing or buffing compound such as MAAS or even Turtle Wax. Most vintage scales are made from animal horn, bone, celluloid or plastic and should do well with these and similar products. Toothpicks and cotton-swabs are your best friend for getting into the hard-to-reach places in this process.

4) Carefully clean off any residue from the buffing process with a fresh cotton cloth, and disinfect using a rubbing alcohol or even barbicide, which can be found at local beauty supply stores.

5) You can tighten the pins that hold together the razor scales using a ball-peen hammer. The original pins are formed by “peening” or mushrooming out the ends of a piece of metal. If the razor becomes loose in the handles, just tap the pins evenly on both sides lightly until it has tightened up again. Take your time with this–hitting too hard can damage or even crack older and delicate scales.

IMPORTANT TIPS

- Follow any and all manufacturer instructions when using a power tool and make sure to wear protective eye, hand, and face garments.

- It’s important to note that when using a power tool with your straight razor blade that you don’t damage the temper or hardness of the metal by getting it too hot. Use a glass of cold water to dunk your blade in during the process—it should never get too hot to touch with your bare hands.

- Avoid sanding/buffing of the razor’s bevel/cutting edge.

- Always remember you’re working with a sharpened piece of steel and treat it with the same respect you would a very sharp kitchen knife.

Further Straight Razor Restoration

Even when using the methods above, you may encounter a straight razor that needs a further step of restoration. Perhaps it is a great blade that just has severe pitting, or maybe a classic razor with a set of broken scales. The use of greaseless buffing compounds, high power buffing machines and even custom made replacement scales need to be employed at times when doing heavy and ongoing restoration.

These more specialized methods of restoration can be done by professionals. With these restoration methods, you should be able to make that nasty looking razor shown above clean up like this:

Final Thoughts

This article is by no means a complete or comprehensive guide to restoring a vintage straight razor. It is intended to be a starting point for those interested yet unfamiliar with where to begin. There are hundreds of shaving-forum threads and countless Wikipedia entries that cover every possible aspect of restoration and honing that you can spend hours if not days poring over. However, all of the information out there can often make the practice look too daunting to even want to attempt or make you feel as if there are some pre-requisite skills you need to have in order to attempt or learn any of this.

That’s why we created this article to really cover the highlights and the “down and dirty” information that you need for your first attempt at cleaning up a straight razor and getting it to look great again. Part of the appeal to the traditional wet shaving approach is accessibility and a spirit of “do-it-yourself.” Don’t be afraid to purchase a razor and try these methods out—if you ruin or damage the blade or make a mistake, it’s okay! However, I’m a firm believer that restoring a vintage razor isn’t rocket science and can be carried out by even a novice if done in a methodical, careful, and thoughtful manner.

We hope that by reading this article you feel inspired to shop, purchase and restore a vintage straight razor. Straight razor shaving and restoration are terrific hobbies that can provide tremendous pleasure and a great feeling of accomplishment.

____________________________________________________________________________________________________________________

Matt Pisarcik and Sebastian Sandersius are the vintage razor experts at RazorEmporium.com. These guys sell vintage razors that they meticulously restore to their old luster and also offer razor restoration, where you can send in your old razor to be refurbished. I can personally vouch for their awesome services; they made my great-grandpa’s 19th century straight razor look brand new. I couldn’t believe how shiny and handsome they made it. It was pretty amazing.