Today we return to our series called Toolmanship. The goal of this series is to pass on the basics of tool use to a generation of men who never got around to learning how to be handy.

In this edition, we turn our attention to the lowly hand screwdriver. We’ll take a look at the different types of screwdrivers, how to use one effectively, and tips on maintaining your screwdrivers so you can pass them down to your grandsons.

Parts of a Screwdriver

The screwdriver consists of four parts: 1) The handle, 2) the shank, 3) the blade, and 4) the tip.

Types of Screwdrivers

Screwdrivers are distinguished from each other based on their tip and what type of screw they drive. The two most common screwdriver tips are 1) the slot head screwdriver, and 2) the Phillips-head screwdriver.

Slot head screwdriver (Flathead/regular screwdriver). A slot head screwdriver consists of a single, flat blade that fits in the single slot of traditional screws. It’s the oldest and most common screwdriver in the world.

Phillips-head Screwdriver. A Phillips-head screwdriver has a four star point at the end that fits into the corresponding screw’s shallow, cross-shaped depression. This design allows a user to apply more torque than is possible with a flathead screwdriver. The depression forces the blades of the Phillips screwdriver to slip out before any damaging over-torquing can occur.

While these are the most common screwdrivers, several other types exist for different jobs. Browse this site to see the different types of screwdrivers.

What Screwdrivers Do You Need in Your Toolbox?

You don’t need too many screwdrivers in your toolbox. Below is a suggested list of screwdrivers that will ensure you can handle any job you might face at home.

- Heavy-duty square blade. A long, heavy-duty square blade screwdriver will come in handy for those jobs when you need a lot of torque and driving power.

- Medium and small slot screwdriver.

- Cabinet Screwdriver. A cabinet screwdriver has a thinner shank than most screwdrivers. The thin shank allows the tip to reach screws in deep holes without damaging the surrounding wood. Additionally, the tip on a cabinet screwdriver is straight as opposed to tapered as on a traditional flathead screwdriver.

- Medium Phillips screwdriver.

- Stubby Phillips screwdriver. Use a stubby screwdriver when you don’t have much space to work.

- Ratchet screwdriver. If you do a lot of screwdriving, you might want to invest in a ratchet screwdriver. Like the name says, this screwdriver has a ratcheting device that locks the shank in place when turning clockwise, but then loosens when turning counter-clockwise. Instead of having to take the screwdriver tip out of the screw every time you make a rotation, you can leave it in the screw and just ratchet back to your starting position.

Select the Correct Screwdriver

The biggest mistake people make when using a screwdriver is using the wrong kind for the job. Consequently, they either strip the screw, making it difficult to remove if they need to, or they damage a perfectly good screwdriver. Avoid these headaches by following these tips.

Slot head screwdrivers for slot screws, Phillips-head screwdrivers for Phillips-head screws. You’d think this would be obvious, but a lot of men will take a flathead screwdriver to a Phillips screw when they don’t have a Phillips-head screwdriver handy. Don’t be that guy. Sure, you might be able to get away with it a few times, but you’re risking stripping the screw or damaging the blade on your screwdriver.

Use the right tip size. The tip of the screwdriver should completely fill the slot of the screw you’re driving or removing. If the tip is too narrow, there will be considerable loss of leverage while driving, which means you’ll have to use more muscle to drive the screw. Also, you risk stripping the screw and bending the tip of your screwdriver.

If the tip is too wide, you risk damaging the surface you’re screwing into.

If the tip is too thick, the blade won’t fit in the screw slot and will just slip out as you’re driving.

To help you get the right screwdriver for the job, use this screwdriver sizing chart.

Slot-headed Screwdrivers and Screws

| Blade Size | Screw Size |

| 3/32” | O and 1 |

| 1/8” | 2 |

| 5/32” | 3 |

| 3/16” | 4 and 5 |

| 1/4” | 6 and 7 |

| 5/16” | 8 to 10 |

| 3/8” | 12 to 14 |

| 7/16” | 16 to 18 |

| 1/2” | 18 to 24 |

Phillips-head Screwdrivers and Screws

| Blade Size | Screw Size |

| 0 | O and 1 |

| 1 | 2 to 4 |

| 2 | 5 to 9 |

| 3 | 10 to 16 |

| 4 | 18 to 24 |

How to Use a Screwdriver

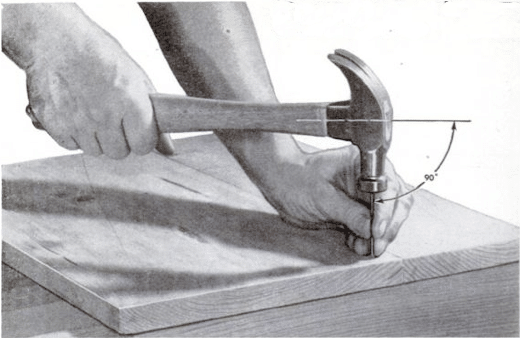

Create a pilot hole. When driving screws into wood, it’s a good idea to drill a pilot hole first. Without pilot holes, screws tend to follow the grain of the wood, which results in crooked screws. Thus, pilot holes ensure that you drive the screw in straight.

Moreover, pilot holes prevent the wood from splinting as you drive the screw in. For small screws in softwood, make a pilot hole by using a punch hole and an awl. For larger sized screws and all screws in hardwood, drill a pilot hole with a boring tool of some kind.

Start the screw. Place the screw on the driver tip and hold both screw and tip together with the fingers of one hand. Apply very little pressure on the driver while turning in a clockwise direction until the screw engages the wood.

Keep driving. When the screw’s thread engages with the wood, move your fingers that were holding the screw in place to the screwdriver shank. Use these fingers as a guide to hold the tip directly in line with the screw. Apply enough pressure on the driver to keep it in the slot.

Screwdriver Tips From Grandpa

Rub beeswax or soap on screw threads. This makes screws easier to drive, especially in hardwood.

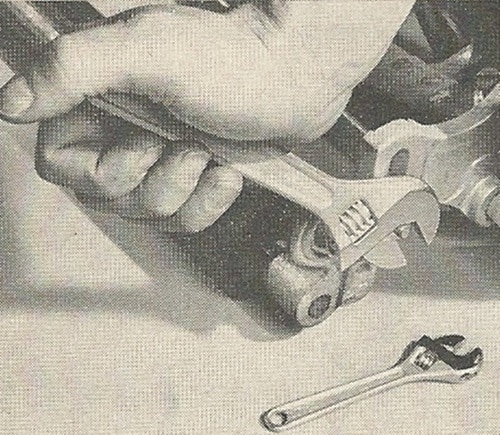

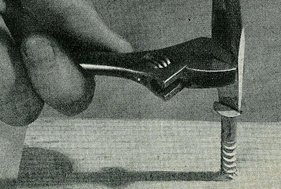

Get more leverage with an adjustable wrench. If you’re driving or removing a particularly stubborn screw, add an adjustable wrench to the equation. Grip the wrench onto the tip of the screwdriver’s blade. As you turn the screwdriver, turn the wrench. This will give you a bit more leverage to move even the most stubborn of screws.

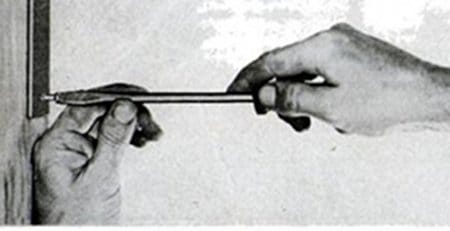

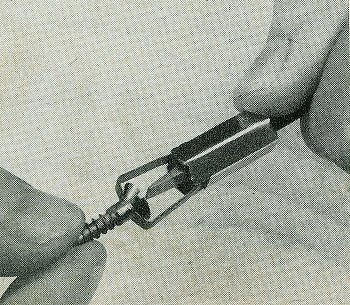

For tough to reach places, use a screw holder. Sometimes you just can’t get your hands into a place to hold a screw as you start driving it. For moments like this, bust out a screw holder. It’s placed on the end of your screwdriver and has a set of jaws that holds the screw in place as you start the driving.

Get more power. For more driving power, use a screwdriver with a shorter shank. Also, try exerting downward pressure on the top of the screwdriver with your free hand.

Maintaining Your Screwdrivers

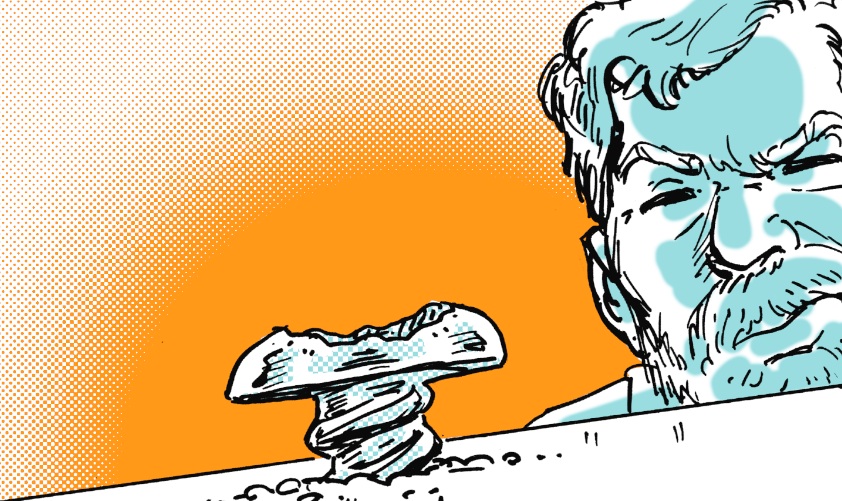

Use screwdrivers for driving screws only. Screwdrivers do one job: drive and draw screws. They shouldn’t be used as putty knives and wood chisels, for opening paint cans, or stabbling famous cyclists. Using your screwdriver for a purpose it wasn’t meant for will only result in a damaged screwdriver and life in jail.

Keep the tip square (just like your chin). No matter how much care you take with your screwdrivers, they’re bound to get worn or chipped. If you notice your screwdriver’s tip getting a bit rounded or chipped, avoid using it. You risk the screwdriver slipping from the screw and either injuring yourself or the surface that you’re screwing into. To correct any rounding or chipping in your tip, just grind it square with a bench grinder. Avoid overheating the tip. You’ll mess up the metal’s temper if you do.

Oil things up. To avoid rusting, keep your tools stored in a cool, dry place. It also doesn’t hurt to rub the shank down with oil and take some steel wool to your screwdrivers every now and then.

Can’t I Just Use a Power Screwdriver?

I bet many of you are asking, “Can’t I just use a power screwdriver?” Indeed you can. If you plan on driving a ton of screws, an investment in a quality power screwdriver might be worth it. However, be careful when using power screwdrivers or power drills that can be converted to screwdrivers. They often provide more torque and power than you need, which, if you’re not careful, can result in damage to the wood or stripping the screw. Driving a screw by hand prevents that because you can “feel” when the screw is tight enough.

If you don’t plan on doing a ton of screwing (you’re done sewing your wild tool oats), then you can get by with just a set of manual screwdrivers.

Further Reading:

Toolmanship: Wrenches

Toolmanship: Handsaw

Toolmanship: Hammer