A stripped screw is a screw in which the head has become worn or damaged to the point where the tip of a screwdriver or the driver bit of a drill has difficulty gripping the screw in order to turn it.

We’ve talked before about how to address the problem and remove stripped screws.

But as the old saying goes, an ounce of prevention is worth a pound of cure.

What can you do to prevent stripped screws in the first place?

Below we provide some tips/useful reminders on preventing screws from stripping.

How to Prevent Stripped Screws

A screw can become stripped in several ways.

The “drive” of a screw — its recessed socket — can be damaged from the screw being repeatedly screwed in and out or from the screw being overtightened.

Screws also frequently strip due to “cam-out.”

What’s cam-out, you ask?

Cam-out is when a drill bit slips out of the screw’s drive/socket while you’re drilling.

When a drill’s driver bit cams out of the fastener’s head, it usually keeps spinning hundreds of times before you let go of the trigger. As the bit continues to spin while not securely locked into the screw’s socket, it strips out pieces of its metal. Do that enough times, and you’ve got yourself a stripped screw that’s harder for your screwdriver/drill to grip, and thus turn and extract.

So to prevent stripped screws, you want to prevent cam-out; here’s how:

Use the Correct Bit Size for Your Screw. You’d think this would be a no-brainer, but a lot of cam-out happens because someone uses a driver bit that’s either too big or too small for the screw’s socket. To ensure you get a proper lock between bit and screw, use the correct size bit!

If the box says the screw is a #2 screw, use a #2 screw bit.

It should indeed be a no-brainer.

Get Rid of Beat-Up Driver Bits. Related to using the correct bit size for your screw, is discarding old, beat-up driver bits. When a bit wears out, it loses its ability to get a secure lock in the screw, and cam-out results.

If you notice that you’re getting a lot of cam-out while driving in a screw, try swapping in a new bit. It might be just the thing you need.

Apply Adequate and Constant Pressure. When driving a screw with a power drill, you don’t want to put the drill on its fastest speed, but you do need to apply plenty of pressure. This will help prevent the driver from skipping out of the screw’s head, thus preventing cam-out and screw stripping.

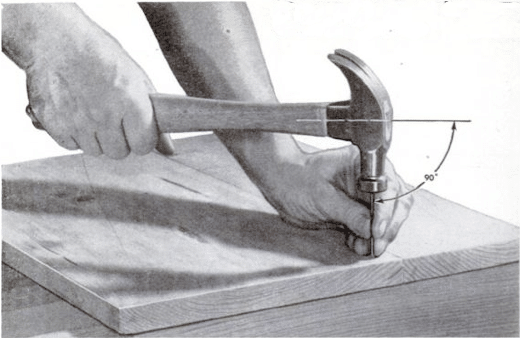

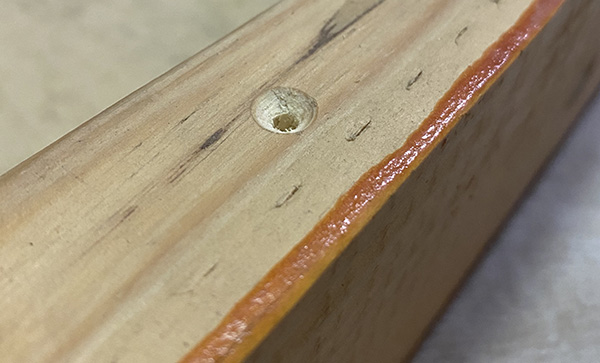

Create a Pilot Hole. Construction screws will usually go into wood smooth as butter. But there are times when you’re driving a screw into wood that the screw gets stuck, leading to cam-out. To prevent that, drill a pilot hole for your screw. Get a drill bit that’s slightly smaller than the screw and drill a hole. Place screw tip in hole and drive.

Besides reducing cam-out (and thus screw stripping), drilling pilot holes can help prevent the wood from splitting while you’re driving the screw in.

For extra handyman points, create a countersink when you drill your pilot hole.

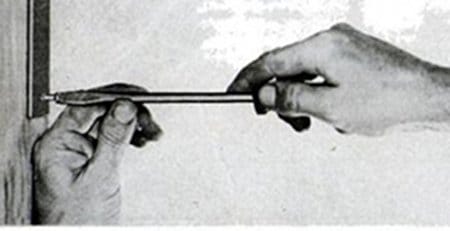

Use a Bit Holder. Cam-out can be caused by not having a driver bit aligned properly in the screw’s socket. You want to drive directly in line with the axis of the screw; if you’ve got the bit in there at an angle, you’re not going to get a lock, and you’re going to get cam-out.

To get alignment between the bit and screw head, consider using a bit holder instead of putting the bit directly in your drill’s chuck.

The bit holder’s long shaft will let you better see if the bit is properly aligned with the screw.

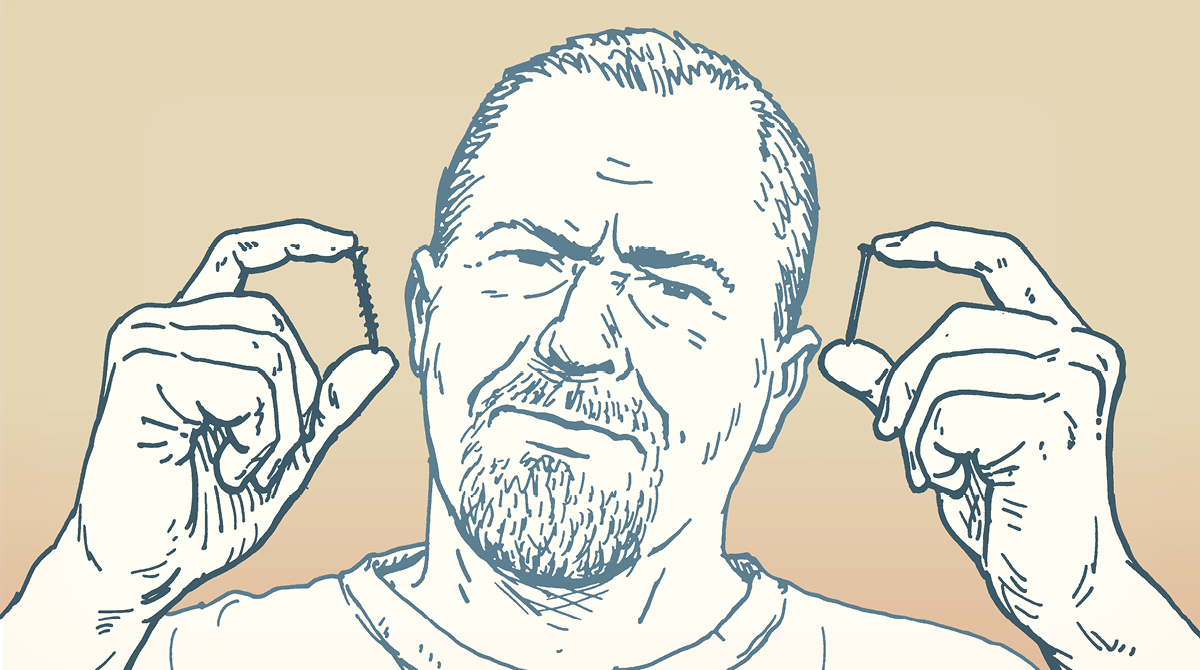

Use Torx Construction Screws. A Phillips head screw is more likely to cam out due to the design of its drive. According to Handyman’s World, the cross-shaped recess of a Phillips head screw “is tapered towards the center, and the tip of the screwdriver is also tapered. When the screwdriver is turned, force is applied laterally, which causes the tip to be pushed outwards.”

If you want to avoid the cam-out that often occurs with Phillips head screws, consider switching to Torx screws. Torx screws have a star-shaped recess and require a Torx bit driver to drive them. They provide a better lock and reduce the chances of cam-out, and thus screw stripping.